The Ultimate Guide to Hydraulic Motor Parts: Choosing the Right Supplier

In today’s world, where machinery is pivotal across industries, the importance of reliable components cannot be overstated. A hydraulic motor parts supplier plays a crucial role in ensuring the efficiency and longevity of hydraulic systems used in a wide range of applications, from automotive to industrial machinery. This article explores everything you need to know about selecting the right supplier, the benefits of quality hydraulic components, and the best practices for maintaining these vital parts.

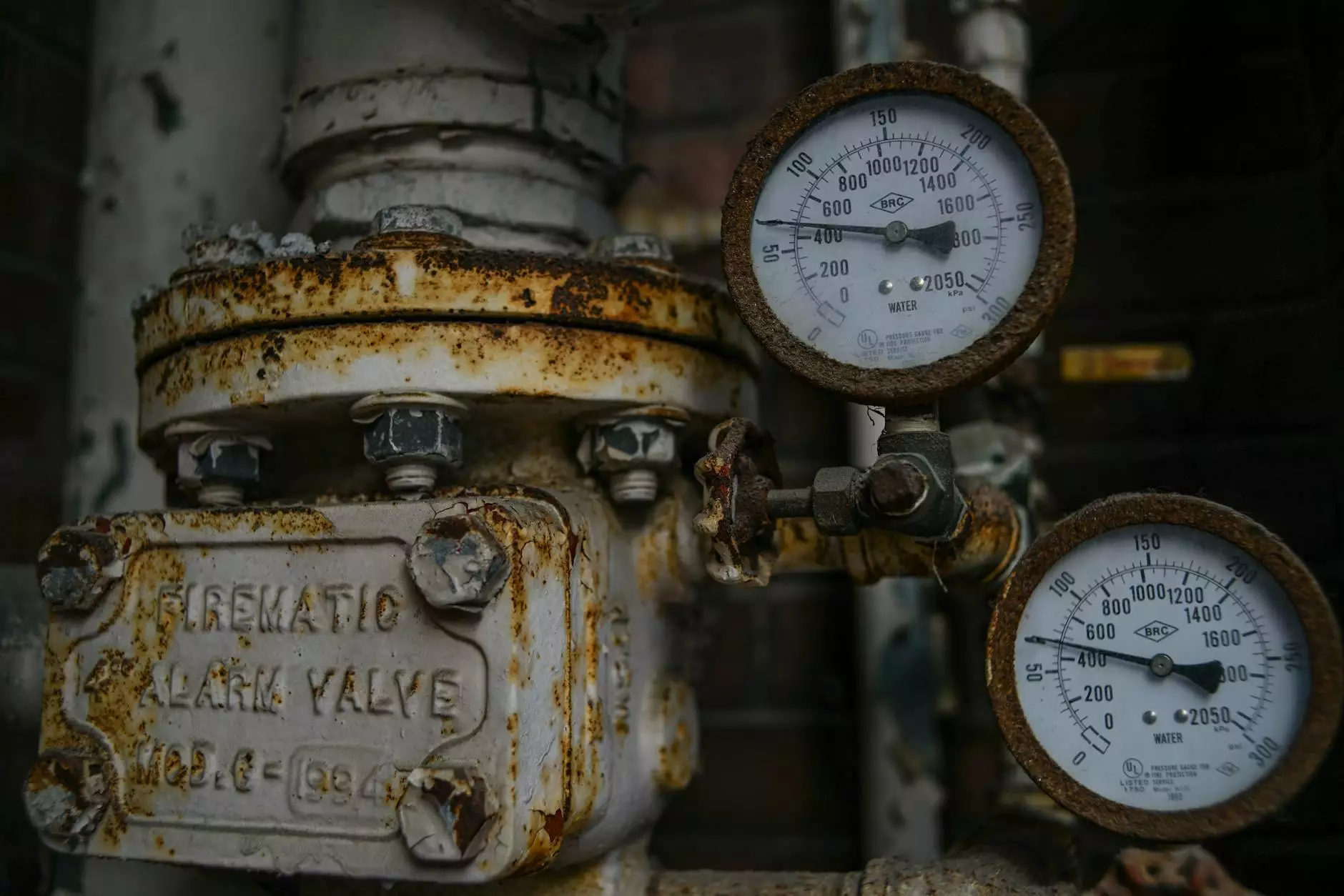

Understanding Hydraulic Motors and Their Parts

Hydraulic motors are devices that convert hydraulic energy into mechanical energy. They are essential in numerous applications, including construction machinery, automotive systems, and motorcycle drivetrains. To keep these motors functioning optimally, high-quality parts are non-negotiable. Some of the essential components include:

- Hydraulic Cylinders: Essential for converting hydraulic pressure into linear motion.

- Pumps: Vital for circulating hydraulic fluid and maintaining pressure.

- Seals and Gaskets: Prevent leaks and ensure that systems operate efficiently.

- Control Valves: Regulate the flow of hydraulic fluid, ensuring precise control over motor operation.

- Filters: Keep the hydraulic fluid clean, avoiding damage to motor components.

Why Quality Matters in Hydraulic Parts

The performance of hydraulic motors largely depends on the quality of parts used. High-quality hydraulic components contribute to:

- Increased Longevity: Durable parts last longer, reducing replacement frequency.

- Enhanced Performance: Quality parts ensure smooth operation under various conditions.

- Cost Efficiency: While initially more expensive, high-quality parts often lead to lower overall maintenance and replacement costs.

- Improved Safety: Reliable components reduce the risk of failure, enhancing safety for operators and machinery.

Choosing the Right Hydraulic Motor Parts Supplier

With numerous suppliers available, selecting the right hydraulic motor parts supplier is crucial. Here are key factors to consider:

1. Product Range

A reputable supplier should offer a wide range of hydraulic parts, including those specific to both automotive and motorcycle applications. At Shop Hydraulic America, we pride ourselves on our extensive inventory that meets the needs of varied clientele.

2. Quality Assurance

Always check if the supplier adheres to quality standards. Look for certifications like ISO 9001, which indicate a commitment to providing high-quality products. Our parts go through rigorous testing to ensure reliability and performance.

3. Technical Support

Technical expertise can make a significant difference. A good supplier will have knowledgeable staff ready to assist you with product specifications, installation guidance, and troubleshooting. Our team at Shop Hydraulic America is dedicated to helping you choose the right parts for your needs.

4. Competitive Pricing

Price is always a consideration, but it should not compromise quality. Look for a supplier that offers transparent pricing with no hidden fees. At Shop Hydraulic America, we strive to provide the best value for premium hydraulic parts.

5. Customer Reviews and Reputation

Research customer reviews and testimonials to understand the supplier's reputation in the market. A company with a history of satisfied customers is typically a reliable choice.

Benefits of Partnering with a Reliable Hydraulic Motor Parts Supplier

Collaborating with a trusted hydraulic motor parts supplier like Shop Hydraulic America offers numerous advantages:

- Access to a Diverse Product Range: As your operational needs change, having a supplier that keeps various parts available helps minimize downtime.

- Tailored Solutions: The right supplier works with you to provide solutions that meet specific requirements.

- Continued Support: Suppliers committed to customer service will help troubleshoot and provide after-sales support.

- Expert Guidance: With expertise in the industry, you’ll receive valuable advice on the best practices for using and maintaining your hydraulic parts.

Maintenance Tips for Hydraulic Motor Parts

Ensuring the longevity and efficiency of hydraulic motor parts involves regular maintenance. Here are some essential maintenance tips:

1. Conduct Regular Inspections

Regularly inspecting hydraulic components can identify wear and tear before they lead to failure. Look for signs of leaks, unusual noises, and irregular performance.

2. Change Hydraulic Fluid Regularly

Hydraulic fluid serves as the lifeblood of the system. Regularly changing it can prevent contamination and degradation, protecting the motor parts from damage.

3. Keep Components Clean

Dirt and debris can cause catastrophic failure in hydraulic systems. Ensure that seals and reservoirs are clean, and replace filters as needed.

4. Monitor Temperature Ranges

Overheating can lead to component breakdown. Use temperature gauges to monitor the hydraulic system’s operation, ensuring it remains within safe limits.

5. Consult Professionals for Repairs

If you encounter issues, seeking professional help is fundamental. Attempting to fix complex problems without the right expertise can result in further damage.

Conclusion: Elevate Your Operations with the Right Hydraulic Motor Parts Supplier

In conclusion, securing a reliable hydraulic motor parts supplier is vital for businesses that rely on the efficiency of hydraulic systems. By choosing a supplier that offers a comprehensive range of auto parts and supplies as well as motorcycle parts and supplies, such as Shop Hydraulic America, you can ensure your operations run smoothly and effectively. Always prioritize quality, reliability, and customer support when making your choice.

Remember, investing in high-quality parts and making informed choices can lead to substantial long-term savings and operational efficiency. Make the smart choice today and partner with a supplier that understands the importance of performance and quality.